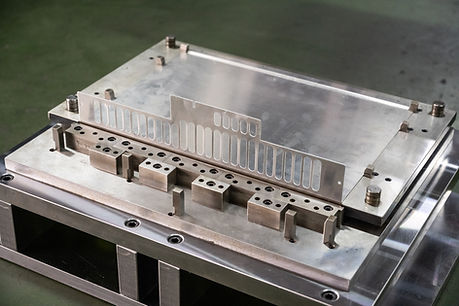

SHEET METAL

FABRICATION

Jinpao provide sheet metal fabrication latest technologies:

Bending - Equipped with a newly-developed AMNC 3i (intelligent, interactive, integrated) control.

Forming - Designed to handle today’s high strength materials with controlled slide motions that can eliminate many secondary operations

01

punching & laser cutting

can cut up to 25mm mild steel, reach up tp 500 hits per minute which equipped with shuttle table to allow unloading and material setting while the machine is running.

PUNCHING & LASER CUTTING

02

HG press brake machines from AMADA can handle a full range of material thicknesses in bend lengths up to 4300mm. Equipped with a newly-developed AMNC 3i (intelligent, interactive, integrated) control, the HG series provides high-speed and high accuracy. Enhanced database network features provide better communication between the CAM program and the AMNC 3i

—resulting in less manual interaction and faster processing.

The HG ARs is a fully-integrated robotic bending system with a 6-axis robot, Automatic Gripper Changer, and Automatic Tool Changer with patented AMADA tooling. Each stage of the bending process, including tool loading, gripper exchange, and robotic bending are all performed at fast speeds to maintain high levels of unmanned machine productivity. We have implemented B2B (Blanking to Bending) automation in our factory.

03

forming

Fluid Cell sheet hydroforming creates parts with a single unmated tool, using the downward force of the pressurized bladder.

JINPAO’s Triform Fluid Cell press can be thought of as high-performance alternatives to traditional solid-block rubber pad forming. Pad forming typically applies pressure of 1,000 – 1,500 PSI on the part, our sheet hydroforming presses offer 5,000 PSI on the part and place uniform pressure on every square mm of the part’s surface. The result is reduced material wrinkling, increased definition, and often it eliminates the need for manual hand-finishing.

Designed to handle today’s high strength materials with controlled slide motions that can eliminate many secondary operations, our AC Servo Press meets the increasing demand for cost effective, consistent and reliable manufacturing. This press with slide accuracy in microns, adjustable stroke for optimum thru-put, fully programmable slide velocity to control reverse loading without loss of energy and dwell for multi-processes such as in–die tapping or part insertions.